fiber ceiling materials

-

...

...

Links

The benefits of using cast iron for spears lie in its inherent properties. Cast iron, known for its excellent castability, is resilient and suitable for manufacturing sharp, sturdy spearheads that can withstand the rigors of battle. The material's high carbon content contributes to its hardness, allowing for effective penetration without easily blunting. Moreover, the casting process enables the creation of complex shapes that traditional methods cannot replicate, leading to innovative spear designs tailored for specific combat contexts.

Colored aluminum windows and doors profiles

Both paint and powder coatings are common solutions, though powder coatings can’t be touched up on site when they chip, which makes them less practical for long term maintenance. we typically hot dip galvanize our wrought iron, which adds a zinc coating to the metal, protecting it from oxidation. We then prime and paint over it for finishing.

Long term, high-end architecture. Wrought iron holds up to harsh weathering longer than steel. It doesn’t corrode as easily or as quickly. If you want to build an ornate fence that will still be standing about a hundred years from now, choose wrought iron. For example, the legendary Johnston Gate of Harvard University is +100 years old and still stands strong.

Complementing our cast iron chairs are our stunning cast iron tables, which serve as focal points for outdoor gatherings and dining experiences. Crafted with meticulous attention to detail, our tables are as durable as they are stylish. From intimate bistro sets to expansive dining tables, we offer options to suit every occasion and aesthetic preference.

In addition to their functional uses, metal leaves in welding also have significant cultural and artistic implications. They are often seen in sculptures, architectural features, and even in custom automotive work, reflecting a blend of traditional craftsmanship and modern technology. These metal leaves, when skillfully welded, can transform a simple structure into a work of art, narrating stories through their intricate designs and patterns.

Extruded aluminum is about 1/3 less than iron or brass, a clear indication it is comparatively a lightweight material.

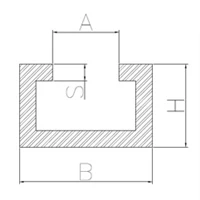

Sliding doors have become a popular choice for homeowners and businesses alike, providing an elegant way to save space while enhancing the aesthetic appeal of interiors. Whether it's a patio door leading to a garden or an interior door separating rooms, the functionality of these doors relies heavily on one crucial component sliding door runner wheels. This article will explore the importance of these wheels, their types, maintenance tips, and how to choose the right ones for your sliding doors.

This die becomes shorter and wider until it can never expand anymore due to container wall restriction. That’s when the aluminum material starts forcing its way out through the die’s orifice and form a particular profile.

As the technical content and the degree of mechanization of doors and windows are not high, most of them rely mostly on the manual operation of the installation workers, which requires the operators to have a good sense of product quality. It is important to strengthen the proficiency of the operators and their product awareness during the production process. High-quality aluminium windows should acquire the following qualities: fine processing, consistent angle (the main frame is usually 45 or 90 degrees), no obvious gaps during the splicing process, good sealing performance and smooth operation.

3. Inspect for Wear and Tear Regularly check the rollers for signs of wear, cracking, or damage. Replace any broken components promptly to avoid further damage.

Not only will your property be more secure, but it will also have an aesthetic upgrade with wrought iron fences. However, such a wall's expense may be the determining factor between wrought iron and cast iron fencing, which is less costly.

They can be easily shaped and formed to create a wide range of designs, including traditional, modern, and contemporary styles They can be easily shaped and formed to create a wide range of designs, including traditional, modern, and contemporary styles

They can be easily shaped and formed to create a wide range of designs, including traditional, modern, and contemporary styles They can be easily shaped and formed to create a wide range of designs, including traditional, modern, and contemporary styles aluminium profiles for doors and windows. This versatility allows architects and designers to create unique and innovative door and window designs that stand out from the crowd.

aluminium profiles for doors and windows. This versatility allows architects and designers to create unique and innovative door and window designs that stand out from the crowd. At Orion Ornamental Iron Inc., they specialize in creating custom iron products that add beauty, elegance, and security to any property. Their team of skilled craftsmen uses the finest materials and innovative techniques to design and fabricate iron products that are both aesthetically pleasing and durable.

Extrusion: The billet is heated and placed onto an extrusion press, which passes it through a die and goes through several processes to ensure it is straight, strong, and of the required quality. The extrusion process includes an automatic production line composed of ingot heating, extrusion, cooling, straightening, cutting, and other processes .

2. Good sealing performance: aluminum doors and windows have high air tightness, water tightness, and sound insulation properties that are better than wooden doors and windows and steel doors and windows.

Deep Processing

Overall, ornamental cast iron manufacturers play a crucial role in preserving and promoting the beauty of cast iron in architectural and decorative applications. Their craftsmanship and expertise ensure that cast iron pieces continue to be valued and admired for generations to come. Whether you're looking to enhance the appearance of your home or business, ornamental cast iron manufacturers can help you achieve a timeless and elegant look that will stand the test of time.

ornamental iron post. Their robust construction acts as a physical barrier, deterring potential intruders while also creating a psychological sense of safety. They also define spaces, marking entrances, boundaries, and pathways with a distinct air of formality and grandeur.

ornamental iron post. Their robust construction acts as a physical barrier, deterring potential intruders while also creating a psychological sense of safety. They also define spaces, marking entrances, boundaries, and pathways with a distinct air of formality and grandeur. Aluminum window frame extrusions have become increasingly popular in the construction and architectural industries due to their numerous advantages over traditional materials. With the growing demand for energy-efficient, durable, and aesthetically appealing windows, aluminum extrusions offer a solution that meets both functional and design needs. This article delves into the key benefits of aluminum window frame extrusions and their impact on modern building practices.